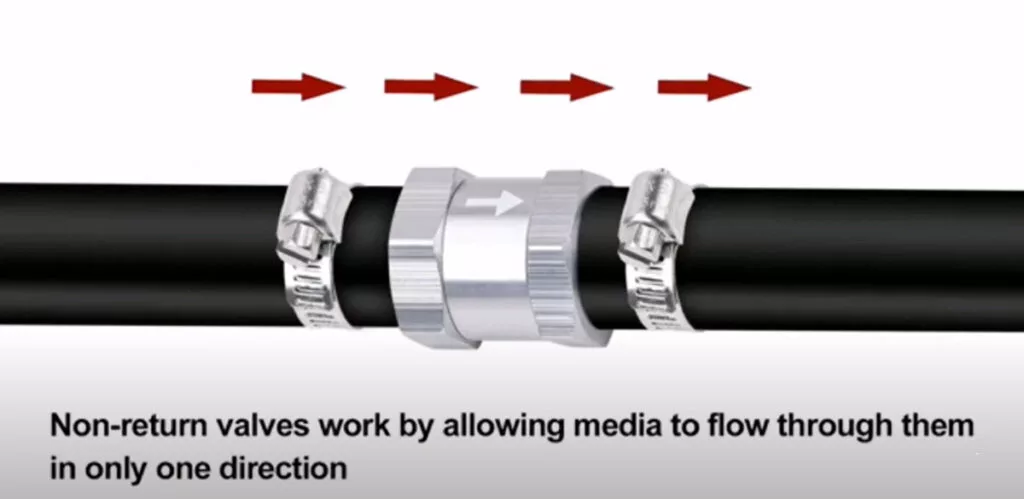

A check valve is a device that only permits one direction of fluid flow. They feature two ports, one for the media intake and one for the media output. They’re known as ‘one way valves‘ or ‘non return valves’ since they only allow material to flow in one direction. A check valve’s primary function is to prevent backflow in the system.

How does one way fuel check valves work?

A pressure difference is required for a check valve to function. They need more pressure on the input side than on the output side to open the valve.

The valve closes when the pressure on the output side is more significant (or when the pressure on the input side is insufficient). The closing mechanism differs depending on the valve type. Unlike other valves, they do not need a handle, lever, actuator, or person to function correctly.

Where does the one way valves are helpful?

Before we go into the details of the one way fuel check valve, let’s have a look at what it’s for. They’re typically used in situations where backflow might be a problem. Non-return valves, on the other hand, are a cheap, effective, and simple solution to a possible problem. Backflow may be problematic if the backflow is polluted, contaminating the medium upstream as a result.

A non-return valve, for example, is installed in a sewage pipe to guarantee that waste may exit but not re-enter the system. They’re also employed if backflow harms upstream equipment that only allows media to flow in one direction.

A reverse osmosis filter, for example, can only allow water to flow in one direction, so a one-way valve is installed downstream to prevent this. There are check valves in a variety of sizes, styles, and materials to guarantee that there is one for every purpose.

What are the types of check valves?

A flexing rubber diaphragm forms a normally-closed valve in a diaphragm check valve. For the check valve to open and allow flow, the pressure on the upstream side must be higher than the pressure on the downstream side by a particular amount, known as the pressure difference. When positive pressure is no longer present, the diaphragm flexes back to its original closed state.

Swing check valve.

A tilting disc or a swing check valve A check valve is one in which the disc, which blocks the flow, swings on a hinge or trunnion, either onto the seat to prevent backward flow or off the seat to allow forward flow.

The seat opening cross-section might be perpendicular to or at an angle to the midline between the two ports. Swing check valves occur in a variety of sizes, although oversized check valves are often swung check valves. Water hammer is a typical problem produced by swing check valves.

Flapper valve.

A flush-toilet mechanism’s flapper valve is an example of this sort of valve. The physical lift of the flapper overcomes the tank pressure that is keeping it closed. It then stays open until the tank empties and gravity pulls the flapper down.

Clapper valves.

The clapper valve is a version of this mechanism that is utilized in applications such as firefighting and fire life safety systems. Only the inflowing direction of a hinged gate stays open. The clapper valve contains a spring that closes the gate when there is no forward pressure.

Stop-check valve.

A stop-check valve is a check valve with an override control that allows the flow to be stopped regardless of flow direction or pressure. It may be purposely shut by an external mechanism, blocking any flow irrespective of forwarding pressure, in addition to locking in reaction to backflow or inadequate forward pressure (typical check-valve behavior).

Lift-check valve.

A lift-check valve is a kind of check valve in which the disc, also known as a lift, may be raised off its seat by a more significant input or upstream fluid pressure, allowing flow to the exit or downstream side.

A guide maintains the disc was moving vertically, allowing the valve to reseat correctly afterward. Gravity or greater downstream pressure will force the disc to fall into its seat, closing the valve and stopping reverse flow when the pressure is no longer higher.

In-line check valve.

A check valve comparable to a lift check valve is an in-line check valve. However, when there is pressure on the upstream side of the valve, the spring will ‘lift’ the valve. The ‘cracking pressure’ is the amount of pressure required on the upstream side of the valve to overcome the spring tension.

The spring will shut the valve when the pressure traveling through it falls below the cracking pressure, preventing backflow in the process.

Duckbill valve.

A duckbill valve is a check valve with a soft tube that protrudes into the downstream side of the valve. Backpressure causes this tube to collapse, shutting off the flow.

Reed valves.

A reed valve is a check valve with an orifice plate sealed by a flexible flat sheet. The cracking pressure is very low, the moving element has a low mass, allowing for quick operation, the flow resistance is mild, and the seal improves when backpressure is applied.

These are often found as the air intake valve for the crankcase volume in two-stroke internal combustion engines and as both the intake and exhaust valves for the cylinder in air compressors (s).

Flow check valve.

A flow check is a check valve that prevents undesired passive gravity flow in hydronic heating and cooling systems.

A flow check is a gravity-closed, flow-lifted heavy metal stopper intended for minimal flow resistance, decades of uninterrupted operation, and self-cleaning of tiny particles often found in hydronic systems from the sealing surfaces.

What happens when a one way fuel check valve goes bad?

A check valve is a device that is designed and put in a line or pipe to allow just one direction of fluid flow. When a check valve breaks, the fluid is allowed to flow in both directions. When a pump is halted, this activity may cause it to fail or the fluid to flow back through it.

FAQs related to one way fuel check valves.

Where do you put a fuel check valve?

The check valve is located near the frame on the feed line from the gasoline pump to the hardline, with the flow direction from the pump.

How do you diagnose a bad check valve?

When should a check valve be replaced?

Look for corrosion, rust, or mineral deposits. If the valve has substantial leaks or worn/broken parts, it should be replaced. Check the valves for seizing by opening and closing them. Examine the pressure and temperature of the fluid passing through.

I hope you enjoyed the essay and gained a better understanding of ” One way fuel check valve”. If you have any further questions, please leave a comment below and we will respond with more competent solutions. Also, if you’re interested in learning more about Fuel Inlet Valve matters, click here.